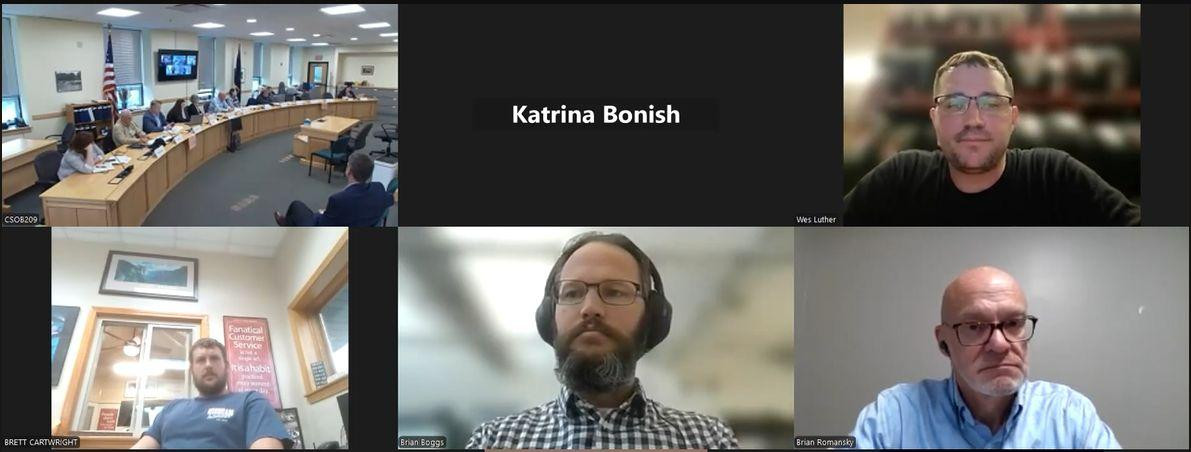

The Maine Automotive Right to Repair Working Group during its September meeting considered issues including independent repairers’ current access to OEMs’ diagnostic data, cost effectiveness of diagnostic systems used by repair shops, and creation of an online portal for repairers and OEMs to share data.

“It’s turning into a tug-of-war match with manufacturers and independent repair shops,” Wes Luther, technician for VIP Tires and Service in Kittery, ME, said during the Sept. 26 meeting. “If you do not have the right stuff and have access to it, the manufacturers are going to monopolize everything, because the only thing we’re going to be stuck doing is tires and basic, basic stuff.”

A new law created Maine’s right to repair working group in August. The law tasks the working group with drafting legislative recommendations by Feb. 28, to chart the creation of a state-run entity that will ultimately draft and enforce right to repair regulations in Maine. The Maine Attorney General’s Office is hosting monthly public meetings of the group to help frame the forthcoming recommendations.

Though federal right to repair legislation recently died in the U.S. House Energy and Commerce Committee, right to repair policies have advanced in states in recent years, and remain a hot topic in the automotive world.

Industry advocates and private citizens as of early September had sent more than 114,000 total letters to Congress requesting the passage of right to repair legislation, according to a press release by the Auto Care Association (ACA). And in August 2023, the National Highway Transportation Safety Administration finally agreed that automakers are able to comply with a 2020 Massachusetts law giving consumers the right to use a mobile app to directly access all of a vehicle’s mechanical data.

Every year, right to repair legislation is introduced in several state legislatures, but usually languishes before having the chance to be enacted.

‘Fair and Reasonable’ Terms for Data Access

Brett Cartwright, owner/operator of Windham Automotive in Windham, ME, noted it is more difficult to get data on newer cars than older ones.

He said his shop pays for a third-party scan tool subscription that updates with new vehicle info on a bimonthly basis, but it’s not a cure-all.

Compared to many cars made since 2020, for instance, “I can get more information on, say, a 2011 Chevy Malibu,” he said.

Everything in new cars has an electronic module, even traditionally basic components like power steering racks, Luther said. This means that shops that don’t have adequate passthrough devices will be left behind, he added.

Third-party passthrough companies often charge per-scan fees ranging from roughly $75 to $150 to use their devices for each repair instance, according to Society of Collision Repair Specialists (SCRS) board member Kris Burton, who is also owner/operator of Rosslyn Auto Body in Alexandria, VA. His shop performs pre- and post-repair scans, and sometimes performs calibration scans with that third-party software, to ensure cars’ issues are accurately identified and the correct repairs made.

While scan tools can generally stream live data and partially calibrate vehicle control modules, passthrough devices are able to more deeply reprogram vehicle control modules. Both OEMs and third-party companies sell passthrough devices.

Tesla Director of Service Engineering Brian Boggs mentioned a 2014 memorandum of understanding (MOU), a 2023 repair data sharing commitment, and the recently passed Maine right to repair working group legislation, all of which require car manufacturers sell their scan tool to independent repairers at “fair and reasonable terms,” he said.

The MOU signed by leaders of the Auto Alliance, Automotive Aftermarket Industry Association (now ACA), Global Automakers, and Coalition for Auto Repair Equity generally calls for due consideration of costs to car dealerships and independent repairers for providing and obtaining the information, respectively.

The 2023 Automotive Repair Data/Sharing Commitment between the Automotive Service Association, SCRS and the Alliance for Automotive Innovation called for “fair and reasonable terms” for data sharing to be established in alignment with U.S. Environmental Protection Agency, California Air Resources Board and Massachusetts statutory requirements.

The “fair and reasonable” provisions of the above guidelines are meant to ensure car manufacturers’ OEM scan tools remain widely available to independent shops, meaning the OEMs “don’t have a monopoly” on the scan tool market, Boggs said.

Universal vs. OEM Scan Tools

Cartwright’s shop uses a universal, third-party scan tool, made by Snap-on, which aggregates data across several different car makes and models, acting as a value-add for repairers who don’t want to pay separately for OEMs’ much more detailed and exclusive diagnostic tools, he said.

To get a comprehensive list of diagnostics for every make and model, “we would need to buy a Ford scan tool, a Dodge scan tool, a Chevy scan tool, a BMW scan tool, a Honda scan tool, a Toyota scan tool,” Cartwright said. “At $10,000 to $15,000 apiece, it’s just not feasible.”

Patrick Horan, owner of Kittery, ME-based Autoworks Diagnostics and Repair, made the case for OEMs’ vehicle data to be provided to independent shops on an ongoing basis, so that repairers could address drivers’ periodic car problems as they arise. But Horan said he didn’t expect Maine’s right to repair regulations to spur this type of data flow.

“These vehicles, as they’re driving, are taking data every day,” he said. “If you have an intermittent problem on your vehicle, if I had the access to it, I could go into your vehicle and see what’s going on when the problem is actually happening to save you a trip to the dealership or to our shop. And that’s the piece that I don’t think we’re going to have access to, which I think is unfair, because that information should be up to the customer who gets to share that information.”

Burton, whose shop is OEM-certified and uses mainly OEM parts for collision repair, said his shop gets access to all OEM information, as it regularly deals with car manufacturers for training and pulls repair instructions directly from the OEM.

Burton said the biggest challenge he sees in collision repair is reimbursement from insurance companies, not OEM data access.

“When we have a vehicle that comes in that’s damaged, we go through and pull all the OEM repair information, get all the instructions; it tells you where to weld, what types of weld, what types of rivets, where the rivets go,” Burton said. “All the relevant information is there.”

Opposition to Right to Repair Legislation

Voit Ritch, owner of Freeport, ME-based European specialty repair shop Autowerkes Maine, cautioned against right to repair legislation, saying that industry agreements, including the 2014 MOU and 2023 repair data sharing commitment, already fill the would-be role of right to repair legislation.

“Aftermarket-developed and secondary repair information is historically inaccurate and unreliable,” he said. “To think that some entity could develop a reliably functional universal information system is certain to fail. I have been, and currently am, a beta tester for numerous companies’ tools, and none of them have ever proven universally reliable.”

Ritch reiterated Boggs’ point that since the MOU, most manufacturers have offered proprietary factory repair data on a subscription basis. Ritch also mentioned the then-active U.S. House right to repair bill, and the potential for a patchwork of individual state regulations of a large industry issue such as right to repair, which he said could lead to “legal paralysis.”

“Shouldn’t we just let this federal legislation take the lead?” he said. “When the government gets involved with legislation, lawyers become involved, and litigation will commence.”

As OEMs will prospectively offer more remote diagnostics services in future years, Maine Right to Repair Coalition Director Tommy Hickey asked Ritch whether it would be fair to repair shops for OEMs to be able to preemptively call customers when their remote diagnostics identify issues, even if independent shops won’t have access to the same data.

If “I do a good enough job, they’ll want to come to my shop instead of the dealership,” Ritch replied.

Hickey said: “They won’t know to go to you when there’s remote diagnostics you don’t have access to.”

Ritch rebutted: “They can call me on the phone and tell me what’s going on.”

Hickey replied: “Not if the manufacturer and the dealer are reaching out” to the driver.

Soon after this spirited exchange, Maine Chief Deputy Attorney General Christopher Taub turned the attention to the meeting’s remaining presenters, noting that substantive policy debate would occur in future meetings.

Registration Portal and ‘Connected Tools’

Independent repairers hope that as OEMs open access to their vehicle data to independent repairers and consumers, they will both receive inexpensive and comprehensive information to fix their cars.

But there needs to be a reliable mechanism to ensure open access.

A cyber-secure registration portal accessible to multiple parties -- rather than being administered unilaterally by OEMs -- could allow independent repair shops to create accounts and have connected tools that talk directly to the registration portals and vehicles, said Brian Romansky, general manager of connected vehicle solutions for Monroe, CT-based Internet of Things company INTEGRITY Security Services, LLC.

Romansky raised the possibility of repair industry adoption of a Service Oriented Vehicle Diagnostics (SOVD) framework, which the International Standards Organization is in the process of standardizing.

In lieu of using scan tools to physically plug into a car to glean diagnostic data, SOVD contains a technology gateway in the car that acts like a connector for a physical scan tool.

“The logic, the smarts, of the scan tool is still being run by the technician themselves at their local computer or their local shop,” Romansky said. “But the diagnostics gateway in the vehicle is providing access just as if they were plugged in effectively. So, it’s making it seem as if the tool is talking directly to the car, even though it may be at a distance.”

The next meeting of the working group will take place Oct. 16 at the Cross Office Building in Augusta, ME.

Brian Bradley