With the automotive industry undergoing a profound transformation, professionals from more than 170 countries had an opportunity to view the latest vehicle innovations at Automechanika Frankfurt late last year in Frankfurt, Germany, many of which are headed for the U.S. market. Future technology and sustainability were key themes, with a focus on artificial intelligence (AI), electrification and digitization. The event, held every two years, was organized by Messe Frankfurt GmbH.

Detlef Braun, a member of the executive board of Messe Frankfurt, said the automotive industry is continuing to innovate at a breakneck pace and Automechanika featured the most important trends and developments in the industry today.

Some of the educational sessions held in the Body and Paint section included the transformation in preparation and refinish, innovations reshaping body repair, and innovations in AI, automation and sustainability.

As part of the Electric Vehicle Expo, nearly a dozen Chinese auto manufacturers, including BYD and Geely Holding Group, with its brands Geely Auto, Lynk & Co. and ZEEKR, exhibited their EV lineup. CATL showcased its EV battery technology. This included Shenxing PLUS, which enables an approximate 830 km range and a 10-minute charge, and the Qilin battery, a lithium-ion battery pack.

Philipp von Westerholt, the coordinator of business development and automotive events for the Messe Frankfurt Exhibition, described Automechanika as a leading show for professionals in the automotive market. The event began in the early 1970s and primarily focused on the automotive aftermarket. Over the years, organizers have added topics pertaining to the developing automotive industry, including EVs, vehicle technology and mobility.

This is the second time Automechanika has included a dedicated area for Innovation4Mobility.

“For us, it’s important to find a bridge between the OEMs and the aftermarket industry,” von Westerholt explained. “This is the intention with the Innovation4Mobility area.”

He said it emphasizes that Automechanika is not only the leading show for the aftermarket industry internationally, but there is more. In addition to displaying industry technology, there was a networking space to encourage attendees to discuss industry issues.

“The idea is to offer attendees knowledge, so they get inspired,” said von Westerholt.

Innovation4Mobility organized various presentations to attend throughout the show focused on current and future issues. These included electric drive systems, hybrid cooling systems, hydrogen vehicles, sustainable fuels and cybersecurity.

In addition to the indoor Innovation4Mobility area, the Future Mobility Park in the outdoor Agora area allowed visitors to test alternative drive systems from BYD and Volkswagen and learn about e-charging systems, storage technology and batteries, alternative fuels and photovoltaics. An e-offroad vehicle powered by solar power, which reached the highest volcano in the world, was also on display.

The “Workshop of the Future” was organized in collaboration with the Zentralverband Deutsches Kraftfahrzeuggewerbe (ZDK) and the Zukunftswerkstatt 4.0 (Future Mobility Workshop 4.0) of the Institute for the Automotive Industry (IfA). Attendees could view technologies focused on artificial intelligence (AI), robotics, extended reality (XR), automation and digitalization.

Charles Canning, director of Cannings Auto, a third-generation motor body repair shop in Cape Town, South Africa, attended Automechanika for the first time. He said his business is very tech-driven and he came to the event for personal development and to learn about new technology available to stay ahead of the trends.

Charles Canning, director of Cannings Auto in Cape Town, South Africa, attended Automechanika for the first time and came to learn about new technology available.

Charles Canning, director of Cannings Auto in Cape Town, South Africa, attended Automechanika for the first time and came to learn about new technology available.

“There’s a lot to take in and it’s coming at us at a faster rate than I think we expect it to,” he said. “I want to have good insight into that from a business perspective.”

In addition to visiting his suppliers, Canning had an opportunity to listen to presentations and network with attendees. He recently became a director of HALO, a newly launched independent nonprofit company for motor body repairers (panel beaters) in South Africa. There are 11 directors strategically placed across South Africa.

Canning said there is a lot of funding available from local government and insurers in South Africa for smaller shops battling to get into the OEM space.

“I want to show the industry what is available in the insurance and OEM sectors in South Africa to empower motor body repairers to move forward with these trends and technology.”

The following is a summary of some of the products and services offered by exhibitors at the show.

Autel

Autel Europe showcased the MaxiSYS ADAS IA600 and the Intelligent MaxiSYS ADAS IA900WA Wheel Alignment.

Autel Europe showcased the MaxiSYS ADAS IA600 and the Intelligent MaxiSYS ADAS IA900WA Wheel Alignment and launched a new accessory for the IA900WA that allows the alignment of headlights using Matrix technology.

Autel Europe showcased the MaxiSYS ADAS IA600 and the Intelligent MaxiSYS ADAS IA900WA Wheel Alignment and launched a new accessory for the IA900WA that allows the alignment of headlights using Matrix technology.

The IA600 is a portable 3D camera ADAS calibration tool that supports laser calibration technology. Massimo Girlanda, Autel Europe sales manager for diagnostics & ADAS, said it provides accurate calibration placement for ADAS and was designed with a modular frame to make it easy to move and transport.

“With its step-by-step graphic instructions, the IA600 makes the calibration process straightforward and easy to follow,” explained Girlanda. “By aligning with the vehicle’s thrust line, the tool ensures optimal calibration accuracy, even for complex ADAS systems.”

The Intelligent MAXISYS ADAS IA900WA and ADAS calibration frame enables repairers to do a four-wheel alignment and ADAS calibration. It includes lane departure warning targets and boards for calibrations and the MaxiSys Ultra ADAS tablet with alignment and ADAS software. Girlanda said six high-resolution positioning and tracking cameras can monitor vehicle height on a shop lift and the robotic frame is easy to move. He added that the alignment reading accuracy is 0.02 degrees for precise alignments. The company also launched a new accessory at the show for the IA900WA that allows the alignment of headlights using Matrix technology.

Bosch

Bosch featured a variety of products, as well as live demonstrations and previews of future offerings. This included parts and test equipment for collision repairers, such as the DAS 300 S20 calibration and adjustment device. The new HV battery repair kit and ADAS One Solutions software were on display, as well as an updated version of the ESI[tronic] Evolution software for vehicle maintenance, diagnosis and repair.

Bosch introduced the Bosch Vehicle Health Certificate and featured parts and test equipment, the new HV battery repair kit and ADAS One Solutions software, as well as an updated version of the ESI[tronic] Evolution software.

Bosch introduced the Bosch Vehicle Health Certificate and featured parts and test equipment, the new HV battery repair kit and ADAS One Solutions software, as well as an updated version of the ESI[tronic] Evolution software.

The company also introduced the Bosch Vehicle Health Certificate. Using established diagnostics solutions, the data stored in the vehicle is read out remotely from the control units, processed and consolidated in a vehicle-specific Bosch certificate.

Nico Krespach, Bosch’s mobility aftermarket public relations spokesperson, said it’s a quick and easy solution that assesses the status of used vehicles based on software.

The certificate is targeted to body shops, fleet operators, used car dealers, vehicle appraisers and used car sellers and buyers. Krespach said it provides crash history to determine if the vehicle has an impact and from which direction, information about possible overdue service, and current error codes stored in the vehicle system. It can also indicate potential mileage deviation or manipulation. For EVs, it will determine the health status of the high-voltage battery.

“It's going to help with repair planning and writing more accurate estimates,” explained Krespach.

The product will initially be offered to the European market and is expected to be rolled out to the American market.

Circular Economy Solutions GmbH

Circular Economy Solutions GmbH (C-ECO) develops business models for the circular economy and showcased its CoremanNet service at Automechanika’s Sustainability Court.

Circular Economy Solutions GmbH (C-ECO) develops business models for the circular economy and showcased its CoremanNet service at Automechanika’s Sustainability Court.

Circular Economy Solutions GmbH (C-ECO) took part in Automechanika’s Sustainability Court, a dedicated space for companies and presentations focused on sustainability. As a worldwide operation company, C-ECO develops business models for the circular economy and showcased its CoremanNet service. CoremanNet provides a systematic circular economy for used automotive parts. This includes the physical collection, core inspection, warehousing and financial accounting.

“Until now, the economy has mainly operated on a ‘take-make-dispose’ model -- a linear model where every product is bound to reach its ‘end of life,’” according to company representatives.

The CoremanNet App, demonstrated at C-ECO´s booth, links technical vehicle data to used automotive parts to improve the remanufacturing of these components for a second product lifecycle.

“A lot of companies are struggling with core management,” said Markus Wagner, the innovation lead at C-ECO. “They know how to remanufacture their products but I think a major issue for them is how to get the used parts and get them back. Our aim is to enable companies to start and professionalize sustainable business models by taking away the complexity of core management.”

The company inspects old parts worldwide, sorts them for production and provides on-demand used parts to the corresponding remanufacturing plants. CoremanNet handles approximately 4 million used automotive parts worldwide.

DAT

DAT showcased a vehicle damage scanner built by Auto Damage Inspection (ADI).

Raphael Dammann, head of sales strategy at DAT, said the scanner is one of several ways of professionally recording damage. High-resolution cameras document the vehicle’s outer skin as the car is driven through the scanner. The DAT software then uses AI to detect and calculate the damage. The scanner is currently being used at the Düsseldorf airport to analyze vehicle damage on rental cars.

“The car scanner at the DAT stand at the Automechanika Frankfurt 2024 was a real crowd-puller for the numerous trade visitors and the many hundreds of trainees who came to see us,” said Dammann.

He said the vehicle scanner has a lot of potential; the goal is to continue expanding its use.

“Customers appreciate the combination of increased efficiency in everyday work, the documentation of the vehicles at entrance and our AI software FastTrackAI®,” he explained. “This form of convenient claim recording is to be made possible for an even larger group of customers in the future.”

FUTURUS

FUTURUS team members presented augmented reality head-up display (ARHUD) technology.

FUTURUS team members presented augmented reality head-up display (ARHUD) technology.

FUTURUS presented some of its latest technology in head-up display systems. This included the augmented reality head-up display (ARHUD), which uses augmented reality (AR) technology to project navigation guidance information onto the road. It uses virtual arrows that merge with the road to guide the vehicle, providing advanced notice for lane changes, turns, etc., without requiring additional thought from the driver. It also integrates with the AD functions to offer services such as night vision, collision warning, lane keeping, lane departure warning and blind spot warning.

“Compared to WHUD (windshield head-up display), ARHUD significantly enhances the user experience during driving, offering intuitive and effortless driving guidance,” according to the company.

FUTURUS has also developed a WHUD product that replaces traditional instrument panels. The company said it offers a superior optical experience with clarity, fineness and no distortion, double images or graininess. In addition to displaying various information on the dashboard, such as speed, tire pressure, fuel consumption and speed limits, it can project navigation, assisted driving and other multimedia screen information.

SATA

SATA team members, left to right: SATA GmbH Managing Director Florian Kaiser, SATA USA Inc. & SATA Canada President George Varagic, and SATA GmbH Managing Director Mike Carlos Wolf.

SATA team members, left to right: SATA GmbH Managing Director Florian Kaiser, SATA USA Inc. & SATA Canada President George Varagic, and SATA GmbH Managing Director Mike Carlos Wolf.

SATA introduced its Liner Cup System (LCS) during the show. Jari Pfander, head of marketing and communications at SATA, GmbH *& Co. KG, said for shops that prefer working with flow cups -- also known as liner cups -- SATA’s new system fits on all the company’s paint spray guns with a Quick Cup Connector (QCC) connection. No adapter is required. Pfander said this provides a more favorable center of gravity, easier cleaning, low weight and less damage to the spray gun. LCS is available in .40, .65 and .85 liter.

SATA also demonstrated the jet X spray gun, which is available in four versions: the jet x BASIC, jet X DIGITAL ready, jet X DIGITAL and jet X DIGITAL pro.

“The nozzle concept of the jet X is based on the innovative labyrinth airflow system,” explained Pfander. “It guides the air in the nozzle in such a way that it exits each orifice at exactly the same pressure and is free of turbulence and pulsation. This enables painters to achieve fine and homogenous atomization and a new level of surface quality, both for high volume low pressure (HVLP) and reduced pressure (RP) technology.”

The jet X BASIC is an analog version with the same nozzle technology and ergonomics but without digitalization.

The jet X digital-ready spray gun can connect the SATA QAC (Quick Adam Connector) to add a digital adam X or adam X pro without a docking station.

The jet X DIGITAL includes adam X, which measures inlet pressure and temperature in the paint booth, operating time and battery status to ensure precise control and optimum painting results. It also provides the ability to switch from bar to psi.

The jet X DIGITAL pro offers a variety of digital functions and includes the adam X pro, which helps painters analyze and control the painting process. It can display deviations from the target pressure set; if the deviation exceeds .2 bar/29 psi, an optical alarm is triggered.

Snap-On

Snap-on received a 2024 Automechanika Innovation Award in the Workshop & Service Solutions category for the John Bean Tru-Point 3D positioning of ADAS calibration accessories, featuring the TGT-05 and BKT-16.

Snap-on received a 2024 Automechanika Innovation Award in the Workshop & Service Solutions category for the John Bean Tru-Point 3D positioning of ADAS calibration accessories, featuring the TGT-05 and BKT-16.

Snap-on Equipment GmbH showcased several pieces of equipment as part of the Total Shop Solutions (TSS) Snap-on brand. This included the award-winning John Bean Tru-Point ADAS calibration tool that uses advanced camera and target technology to ensure precise placement of ADAS targets and fixtures. The company received a 2024 Automechanika Innovation Award in the Workshop & Service Solutions category for the John Bean Tru-Point 3D positioning of ADAS calibration accessories, featuring the TGT-05 and BKT-16.

The TGT-05 enhances 360-view calibrations for manufacturers using vinyl mats, which the company said is a significant improvement over traditional methods. The BKT-16 advances ADAS accessory placement for blind spot calibrations, streamlining the calibration process.

“We are proud to share that the John Bean Tru-Point 3D Positioning of ADAS Calibration accessories has been judged as the unsurpassed winner of 52 entries in the Workshop & Service Solutions category,” said Mariana Montovaneli, director of marketing for John Bean. “Earning this prestigious award is an exciting moment for all of us and is a reflection of the expertise and dedication of our team.”

Jordan Krebs, product manager for alignment and ADAS in the Americas, said the engineering group put a lot of effort into ensuring the accuracy of the products.

“Customer connection between product management and engineering led the development of these innovative products,” said Krebs. “It was a team effort to ensure the TGT-05 and BKT-16 met our demands for accuracy and improved shop efficiency.”

The booth also featured products from other Total Shop Solutions brands, including Hofmann, Blackhawk, Cartec, Car-O-Liner, Ecotechnics, Josam, Kansas Jack, Pro-Cut and SUN. Hands-on demonstrations were offered for many of the products.

Spanesi

Spanesi team members in front of the ELECTRA all-electric spray booth.

Spanesi team members in front of the ELECTRA all-electric spray booth.

Spanesi showcased a variety of equipment at the show, including the Minibench. Designed to repair small and medium damage, Jeramy Holloway, aftersales director, said it’s sturdy and compact, easy to use and occupies very little space inside a body shop.

“The Minibench can be used for most vehicles, including commercial vehicles, SUVs and 4x4s,” explained Holloway. “Incorporating the Touch electronic system, the Minibench can be used as a lift or straightening bench, with a 6-ton pull column capable of delivering 360° pulls around the entire vehicle.”

Demonstrating its commitment to sustainable development, Spanesi introduced its “GREEN LINE” products that have low environmental impact. The company featured the ELECTRA all-electric spray booth, which is currently being beta-tested in Europe. It uses short-wave infrared lamps distributed inside the cabin and software that optimizes ELECTRA’s performance.

Holloway said it is well suited to all those who need high-productivity painting systems, adding that it reduces cycle times substantially and is more economical and environmentally friendly.

“The operation of a fully electric substation allows significant savings in terms of operating costs in situations in which one enjoys advantages or reductions in the purchase of electricity,” said Holloway.

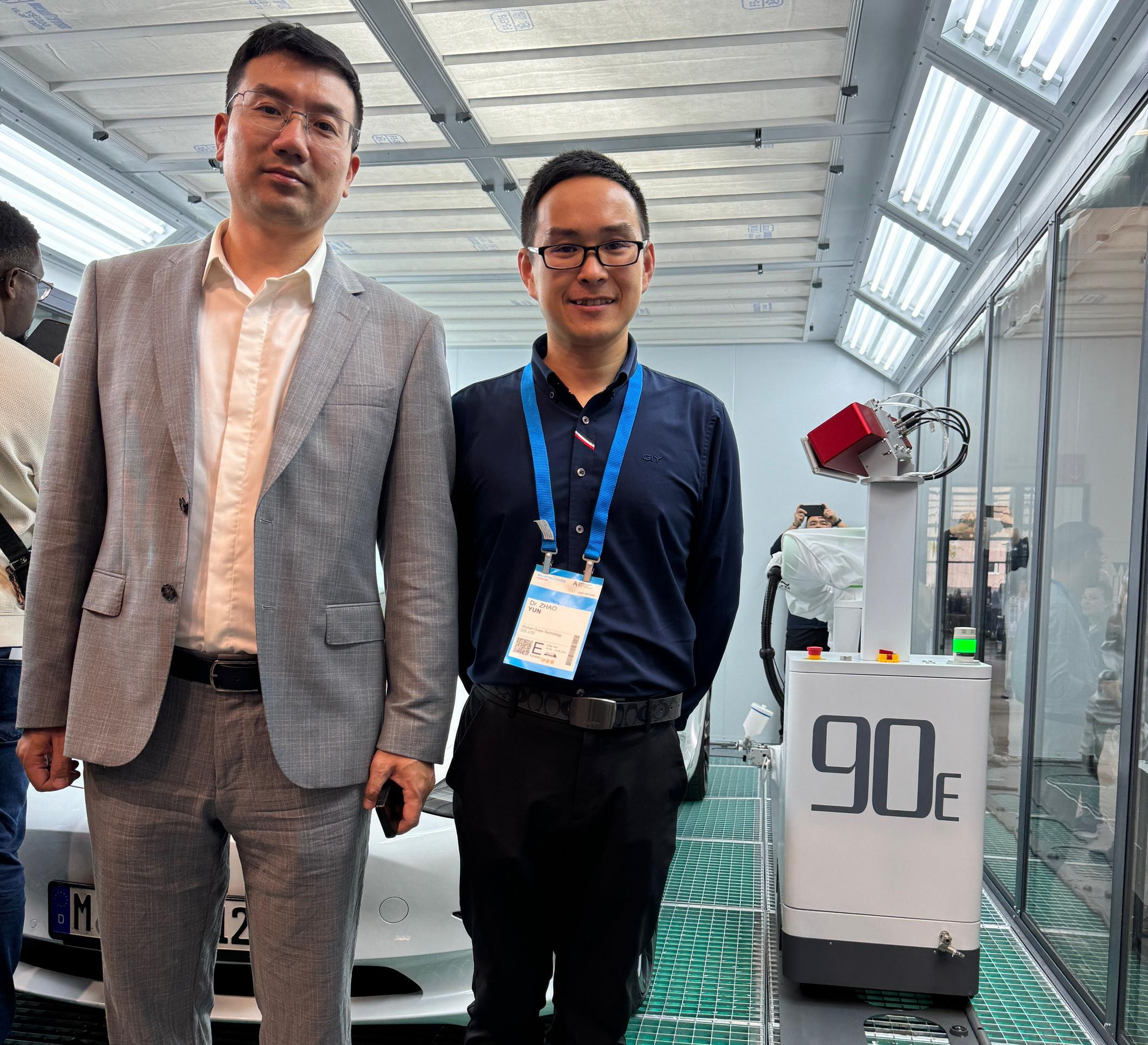

Wuhan Onew Technology Co., Ltd.

The PaintGo Intelligent Spray Painting Robot showcased during Automechanika.

The PaintGo Intelligent Spray Painting Robot showcased during Automechanika.

One of the busier booths at the event displayed the PaintGo Intelligent Spray Painting Robot. The robot is integrated with a wireless machine vision system to identify the work areas that need to be painted. Released in early 2024, the product is now available in Europe, Asia and America.

Eric Zhao, vice president of the overseas business group for Wuhan Onew Technology Co., Ltd., said the robot uses 3D sensors to scan the car and an AI algorithm to identify the work pieces.

"The PaintGo intelligent spray-painting robot system boasts a 'simulation brain' that, based on paint processes, automatically plans the robot's spray path for the target parts and simulates the best evaluation of the painting effect," Zhao explained.

He said installation and operation are extremely simple. The robot is adaptable to a variety of working scenarios and no spray booth modifications are required.

"The PaintGo intelligent spray-painting robot system incorporates a quick-change spray gun mechanism, making cleaning and maintenance more efficient and eco-friendly," he added.

With the predicted shortage of painters over the next decade, Zhao said products like the spraying robot will help shops complete high-quality repairs efficiently.

Stacey Phillips Ronak