As ADAS technology becomes more advanced and more widespread among vehicles coming into to collision shops for repairs, shops that embrace proper calibration processes have a massive opportunity ahead. But they also face challenges in execution, equipment investment and getting paid.

A recent episode of The Collision Vision podcast, driven by Autobody News and hosted by Cole Strandberg, featured Sam Poradish, vice president of insights and innovation at Repairify, to talk about those issues.

Poradish, an ASE-certified master mechanical and collision repair technician, joined asTech – whose parent company is Repairify -- seven years ago as a remote technician providing OEM diagnostics to customers. Since then, he evolved into his current role, which is overseeing software development technologies, data science initiatives and analytics.

The growing prevalence of ADAS equipment is “probably the most tangible change for everybody in automotive repair, mechanical and collision alike,” Poradish said.

“I still remember back in the day when I did my first transmission change that required a transmission programming,” Poradish said. “That was a big change in technology that I wasn't expecting and had to figure out how to solve. I think lots of shops are going through this experience with ADAS equipment.”

According to data collected by asTech’s adasThink product, which scrubs just over 1 million estimates a year, 40% of collision repair estimates now require at least one calibration per OEM requirements, Poradish said.

As that percentage creeps closer to 100%, ADAS calibrations will make less sense to sublet.

“As a shop owner, you don't want to be outsourcing something like that, which does have the opportunity to be a significant profit center for shops on every repair order,” Poradish said.

One of the largest misconceptions about ADAS, Poradish said, is just how prevalent they are – data collected by asTech and other sources like CCC show recalibrations are still being written and theoretically performed at a much lower rate they should be.

“There's still a problem with shops recognizing, on a case-by-case basis, when calibrations need to be performed -- that statistical gap between the two,” Poradish said. “We're still not seeing anywhere close to 100% of everything that should be done per OEM requirements actually being written and performed, which either means systems aren't being repaired to spec, which is a safety and liability concern, or shops are doing them and not recognizing them that they can be a profit center, which also becomes a problem for them over time.”

On the other hand, Poradish thinks another big misconception among shop owners is the “barrier to entry” to be able to handle any ADAS calibrations is too high.

While static calibrations can require advanced targeting systems, dynamic calibrations -- which he said are the fastest-growing segment -- can be performed with just an advanced aftermarket tool or OEM tool.

“Shops look at the entire calibration problem and say, ‘I can't deal with everything. Therefore I'm going to come up with an outsourcing solution for all of it,’ when really there's opportunities,” Poradish said. “Maybe you don't have the facility space or the lighting conditions to dedicate a spot to static calibrations, but dynamics, which just require a drive cycle and a scan tool on a lot of cars -- that's an opportunity that almost every shop can get into and handle in-house.”

How to Get Into ADAS Calibrations

The first step for a collision repair shop is to understand when calibrations need to be done and what equipment, facilities and training are required.

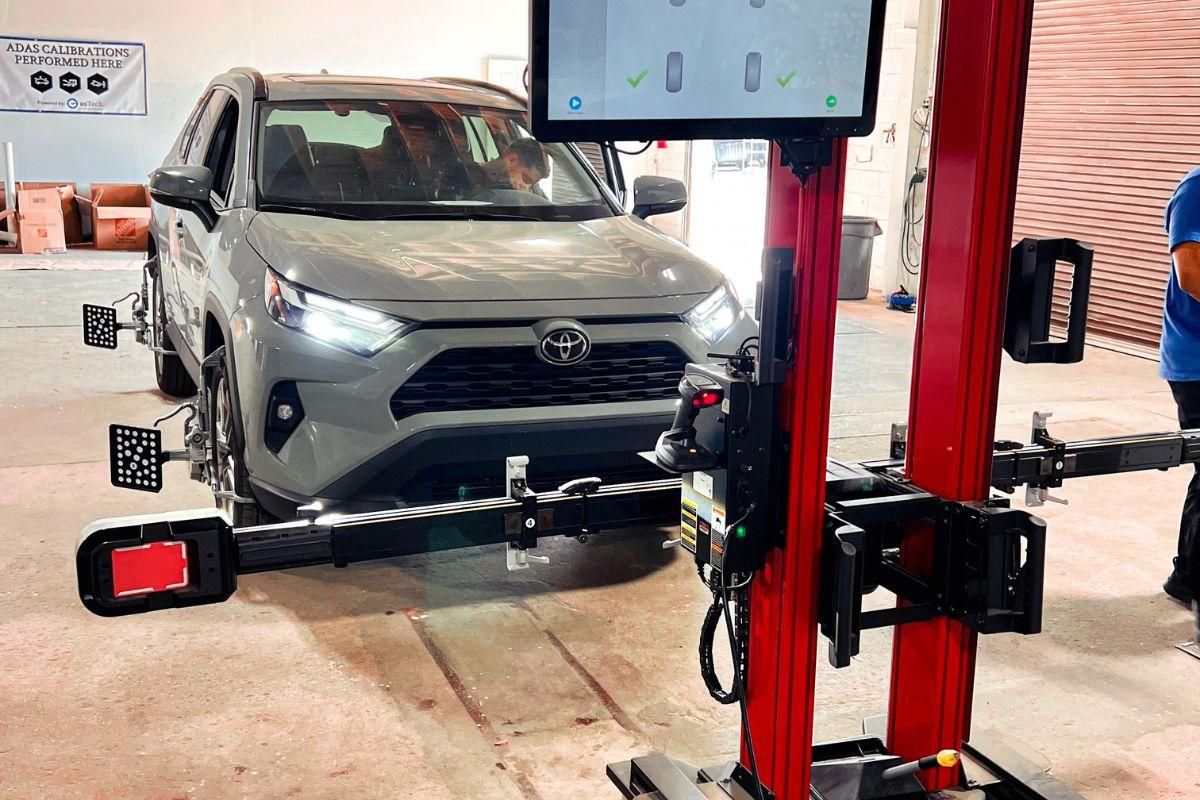

Necessary tools include an estimate scrubber for quick access to OEM repair documentation, which shows requirements and can be provided to an insurer to justify payment; and a scan tool. Poradish said Repairify is “closing the gap” between aftermarket scan tools and OEM-specific ones with the asTech All-in-One, which provides a professional grade aftermarket tool with access to remote OEM tools.

“That's a product that wholly solves the scan tool problem,” Poradish said.

He said Repairify also helps shops finance equipment like calibration frames and targeting packages, “so that they can get started without as much of an upfront investment.”

When a shop owner is interested in performing static calibrations, which have the most stringent facility requirements, Repairify will evaluate its available space to make sure the shop space is capable, or suggest a configuration.

“That’s another common misconception,” Poradish said. “A lot of people think they could just go buy a targeting frame and stick it anywhere, and it's going to work. But they require quite a bit of space actually, to be able to position them for all the different blind spot and radar and camera procedures.

“Lighting is also critical for camera calibrations,” he said. “We see a lot of people setting up targeting frames outside in direct sunlight -- I haven't read an OE procedure which says that's OK yet.

“Best case scenario is the shop’s all in on it and they want to dedicate a space just for performing calibrations, and they have the volume to support it,” Poradish said. “Some of the shops even really see it as a profit center. And they invest in dedicating a space to do their own calibrations and then take calibration work from other shops in the area that might not be able to dedicate the same space.”

Poradish said all shops should look at handling their own dynamic calibrations. “It's really just that scan tool component that you need to solve for in order to be able to do them,” he said.

In 2017, dynamic calibrations represented only about 20% of all calibrations that needed to be performed. Poradish said they are now about 50%. That can partly be attributed to OEMs that prefer a calibration be performed with a dynamic drive cycle, but also allow an option for a static recalibration instead.

“I do think there's a question with the investment in static systems as to how long of a tail do we really have? I would say it's nowhere close at this point to where people should be concerned with making the investment [in static calibration equipment],” he said.

Investing in ADAS Equipment

Performing static calibrations can require tens of thousands of dollars in equipment like frames or targeting systems, so shops need to run the numbers on whether or not they will get enough business to justify that investment.

Repairify offers a program that allows a shop to pay a subscription fee for that equipment to get started, rather than buying it outright, to make sure they will generate enough business to support it.

Part of the return on investment is being able to provide solid documentation to insurance carriers to get paid for following OEM procedures.

“It's very difficult, I think, for someone to argue with an OE-branded position statement that's publicly available that states clearly that a calibration needs to be done when certain conditions are met,” Poradish said.

“The crux of the reimbursement issue is proper documentation. And this is where I think tools like estimate scrubbers are totally invaluable to shops,” he said. “It takes a lot of time to search through and find the exact right document that both justifies and informs on how to complete the procedure. So if all of that can happen instantaneously while you're writing your estimate and have it automatically go into your claims file, it ensures that any time a reimbursement conversation comes up, it's right there, readily available.”

Poradish said OEM position statements have been getting progressively less ambiguous about “certain conditions” that warrant calibrations, which has allowed shops and insurance carriers to more easily agree on when they need to be done.

Repairify has seen shops have more success getting paid for calibrations when they educate the vehicle owner on the importance of calibrations, Poradish said, “especially when they're getting pushback and having [the customer] help lobby carriers to understand and perform these calibrations when they're necessary.”

Poradish said the conversation is already shifting from “Should we be doing these calibrations?” to “How much should we pay for them?”

ADAS Calibration Success Stories

Strandberg asked Poradish to share examples of successful ADAS calibration implementations at shop.

Poradish said Repairify has worked with several shops that have become an independent calibration provider to other businesses.

“A lot of them are [MSOs] where they have multiple shops in an area, and they'll set the facility up in one and direct work from all of their locations to that location,” he said. Then they start soliciting work from other shops.

“I think that’s by far the best way to maximize profit,” Poradish said. “While the facility set up is not inconsequential in terms of costs, the amount of revenue you can make on a mini calibration center, if you're keeping it busy all the time, is really substantial.”

Looking ahead, Poradish said Repairify spends a lot of time analyzing the data it has collected for insight into the future of collision repair as a whole.

“We’re constantly looking at new releases of position statements and repair procedures from the OEs and trying to get ahead of what technologies are coming and what's going to be required by them,” he said, which helps Repairify builds its products to ensure its customers can continue to correctly and safely repair vehicles.

Strandberg asked Poradish what advice he had for shop owners.

“It's just get started or take that next step,” Poradish said. “This isn't going away. Calibrations, electronic repairs in general, are going to be a part of everyday life. I think for most shops it's kind of a part of everyday life already, but it's going to become a part of every claim.

“The good news is it moves slowly. We're going to have some foresight into what's coming, but either gaining the expertise in-house or partnering with somebody that has it, and getting started and seeing what comes in and understanding how it's evolving is really important.”

Abby Andrews